Green Vessel

Environmentally Friendly and Advanced Design of YM U-Type Vessels

Yang Ming always pays much attention to environmental protection. In addition to efficient use of natural resources, preventing pollution and protecting the ocean environment, we actively comply with international conventions and environmental laws/regulations. We make our best to contribute to the environmental protection following the most advanced standards.

In year 2004, Yang Ming was certificated with ISO 14001 proving our software/ hardware

facilities and procedures in the offices/terminals and on the ships conform with

international environmental standard.

In July 2006, Yang Ming joined Business Social Responsibility (BSR) and Clean Cargo

Working Group (CCWG) to promote business social responsibilities and minimize the

effect to the environment in the transportation process.

Our newly built, environmentally friendly 8,200TEU container vessels-U-Type could

clearly illustrate Yang Ming's care about environmental protection and new design

and its main particulars are as below:

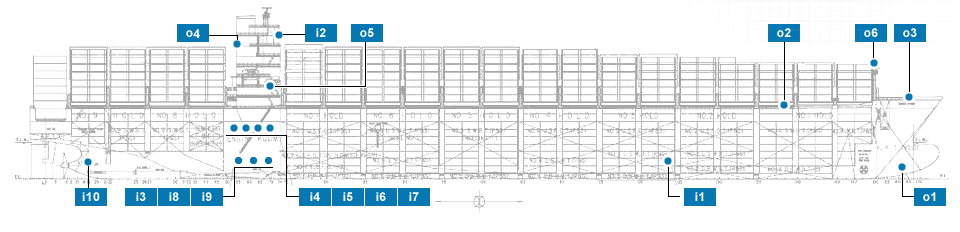

o1

Tin free paint or silicon based

paint on bottom shell

o1

Tin free paint or silicon based

paint on bottom shell

Under water outside shells (vertical & flat bottom areas) are applied with Tin

free instead of Tin-based self-polishing coating (SPC) to prevent from contaminating

aqua marine organisms.

The use of Tin free SPC is in response to growing international concern over the

harmful effects upon organism when Tin is used as anti-foulant on ship's hulls.

There are also applied with 5-year life time coating system that will extend the

dry-docking survey interval and re-application interval of coatings till every five

(5) years. This really eliminates the secondary pollution due to frequent sand ballasting

/ painting repair in dock. “Statement of Voluntary Compliance of Anti-Fouling System”

is issued by Class Society.

o2

Box type Hatch Coaming

o2

Box type Hatch Coaming

Most of ships are suffered from heavy corrosion when aged. The corrosion especially

happened at hatch coaming with open & complicated structures where are exposed

to weather deck. By using of box type, no more open or complicated structures appear

on the outside, and corrosion can be easily noticed that makes maintenance easier

also.

o3

Deck machines are driven by Electric

Motors instead of hydraulic oil system

o3

Deck machines are driven by Electric

Motors instead of hydraulic oil system

It has nothing to do with the oil pollution in case of system is broken.

o4

Air Dust Filter and Water Eliminator

for engine room air intakes

o4

Air Dust Filter and Water Eliminator

for engine room air intakes

Being able to reduce the condensate water coming from M/E air cooler drainage and

further release the bilge separator workload.

o5

Alternative Maritime Power (AMP)

o5

Alternative Maritime Power (AMP)

Ship is fitted with AMP system through which the shore power can be supplied to

ship while the vessel berths at Port of Los Angeles (POLA). Air pollution caused

by running diesel generator engine can be entirely removed.

Specification: AMP to be installed at port side of deck house, including: 6600V,

350A x 2 cables, shore connection panel x 1, control panel x 1, cable reel x 1

o6

Radar on the Fore Sprit

o6

Radar on the Fore Sprit

The vessel is equipped with the 3rd radar on the fore sprit so as to prevent obstructing

of crew's vision from containers. No dead vision exists.

i1

Twin ballast water lines with dilution

function for ballast tanks

i1

Twin ballast water lines with dilution

function for ballast tanks

Two (2) ballast main lines with dilution are adopted and branched to ballast tanks

where the ballast water can be filled in and discharged out through the connections

diagonally placed at tanks simultaneously. By means of dilution method, it contributes

not only time saving of ballast water changing but also to keep same enough stability

of ship at open sea. In addition, the aqua marine organisms can be prohibited from

transplantation through ballast water exchange and the aboriginal marine life can

be protected from invasion of foreigners.Only U1 & U2 type vessels equip with this

system.

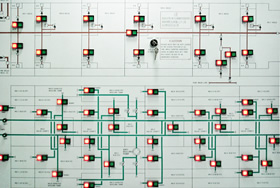

i2

One-Man Bridge Navigation System

i2

One-Man Bridge Navigation System

The ship is designed in compliance with LR One-Man Bridge notation, NAV (ABS : NBL).

The wheel house arrangement and major nautical equipment are well arranged and integrated

on the bridge console where the invisibility is minimized. In addition, the bridge

navigation watch alarm system (BNWAS) is newly introduced for overseeing the on-duty

officer in order to keep whom in position. On the basis of One-Man, no. of watching

crew can be minimized and crews are able to navigate the vessel at their most convenient

to reduce risk of pollution caused by collision.

i3

Vacuum Toilet system

i3

Vacuum Toilet system

Living quarter is fitted with modern Vacuum Toilet system to reduce the consumption

of fresh water as well as to reduce the sewage water.

Meanwhile, the sewage collection tank is enlarged to accommodate the black water

up to 12-day's consumption. Based on the combination effects of both above, the

berthing time at port or sailing time along the coast or in the restricted area

can be extended to fulfill the requirements and reduce the risks of pollution.

i4

Low sulfur fuel oil storage, settling

& service tanks

i4

Low sulfur fuel oil storage, settling

& service tanks

Fitted with independent low sulfur fuel oil tanks, diesel engines have the alternatives

to burn the normal or low sulfur fuel oil to reduce SOx content in exhaust gas emission

so as to meet the MARPOL requirement in restricted area..

i5

M/E Alpha Lubricator

i5

M/E Alpha Lubricator

M/E cylinder lubricating oil is pressure-injected by Alpha lubricator system which

is the brand new design to save the cylinder oil consumption. M/E Alpha lubricator

is a system composing of computer, oil pump, damper, pick-up sensor etc. which delivers

cylinder oil to liner wall exactly based on the piston ring's location inside liner.

So it can spread the cylinder lubricating oil evenly at right timing to cut down

cylinder oil consumption (reduce air emission) as well as extend cylinder liner

service life due to load-dependable injection.

i6

High efficient Main & Generator engines

The ship is equipped with high efficient main engine & generator engine that

fuel oil can be well atomized and combusted to reduce the harmful NOx content in

exhaust gas emission in order to reduce Greenhouse Effect.

All components involved in combustion chambers comply with MARPOL 73/78 Annex VI

Regulation, and are verified by Class Society.

i7

Adoption of refrigerant R-404A

for air condition, provision refrigerating plant and unit coolers. Plants spaces

are also equipped with refrigerant leakage detecting system

By using HFC free refrigerant, there is no direct harmful impact on the environment

to avoid depletion of ozone layer and reduce greenhouse effect. All the pants spaces

are equipped with refrigerant leakage detecting system in order to limit pollution

in the very first time.

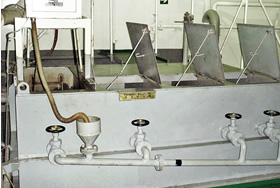

i8

Bilge Primary tank

i8

Bilge Primary tank

The ship is fitted with a large bilge water Primary Tank to pre-separate oil from

oily bilge. It is able to reduce the workload of Oily Bilge Separator as well as

to promote the treatment efficiency of the separator and reduce the possibility

of sea water pollution.

Bilge primary tank capacity: 6.0 M

3

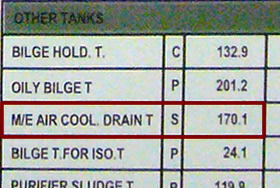

i9

Clean bilge tank

i9

Clean bilge tank

Drain water contaminated by oily content normally from cooler maintenance and oil-contented

coamings of machines that is collected in Bilge Holding Tank and Oily Bilge Tank.

In addition to the above tanks, M/E Air Cooler Drain Tank is designed to collect

the cleaning bilge from M/E air cooler drain. Cleaning bilge in said tank is easily

separated by separator because of light oily contamination. This can reduce workload

of Oily bilge Separator as well as the possibility of seawater pollution.

Capacity of each bilge water tank:

Bilge Holding Tank – 132.85 M

3

M/E Air Cooler Drain Tank – 170.25 M

3

Oily Bilge Tank – 201.37 M

3

i10

Stern tube air seal

i10

Stern tube air seal

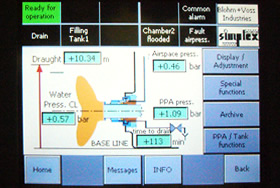

Air guard stern tube seal instead of Simplex seal of propeller shaft uses the air

as a medium to keep the sea water from ingress into engine room along stern tube.

Air guard system is developed by several prestigious makers and introduced to very

large container vessels in the beginning. In case of the occurrence of any seal

ring breakage, only air blown into sea water or sea water ingress into engine room

so as to prevent from lube oil pollution. Possibility of pollution will be limited.